How Can I Reduce Slips and Falls On My Trex Decking?

When we at HandiTreads are asked how to make Trex decking or stairs less slippery, our first question is always, “How old is your Trex decking?” The newer (last five-ish years) of Trex decking seems to have decent but not exceptional traction. However, some of the older Trex decking had problems with flaking and decomposing that could make it slippery to the point of being unsafe.

With that said, the HandiTreads Stop-the-Slip Configurator is an excellent place to begin your evaluation of various slip, trip, or fall conditions. Using a series of questions, the configurator will identify and rank the most effective and efficient solutions for your slippery Trex deck in less than a minute.

Slippery Trex and Composite Wood Steps

If the slick areas of your Trex deck are limited to the steps, then our HandiTreads aluminum non-slip treads are the perfect solution. Not only do they offer greatly improved traction in all weather conditions, but they also come in several designer finishes that will match or complement any Trex color deck. Just as important, attaching our aluminum treads to Trex boards with the appropriate stainless steel screws will not void your warranty. (Because warranties change, it’s important that you read your Trex warranty carefully before purchasing and installing any non-slip tread on Trex stairs.)

What About Grit Tape?

Grit Tape may seem like a solution for composite wood steps, but in the end, they fail. The reason adhesive grit tapes fail on Trex steps is the same reason that paint won’t stick to Trex decking – it’s plastic skin with a faux wood texture.

In outdoor applications, there is zero chance that grit tape will last on composite wood, like Trex, for more than a year. This means you’ll be scraping the old stuff off and starting all over again.

Only Parts of My Trex Deck are Slippery

It’s fairly common for us to hear from customers that only part of their composite or natural wood deck is slippery. For example, virtually every deck could benefit from extra traction directly outside of the sliding glass door. Because there’s almost certainly a drop of a few inches from the inside of the home to the deck, this is a natural slip, trip, and fall hazard.

Another part of a deck that’s often slippery is the areas constantly under shade. These tree-covered spots tend to stay wet, collect leaves and needles, and can grow moss and mold. All of these are natural slip-and-fall hazards that demand attention.

So, what can you do to these slippery areas? One common, temporary solution is to put a mat or rug in the affected area. While this can help with traction, it also creates its own hazard as it’s very easy to catch a toe on the edge of a rug or mat.

Grit paint, as described below, can work on pre-2012 Trex decking, but it’s not an optimal solution for a small section of the deck because it can make the deck look splotchy.

Our customers love our HandiTreads, but they can be a bit expensive when applied to a large area and if your deck isn’t a dark brown, they treads can visually stand out. After all, we understand that one of the reasons people choose Trex and other composite decks is the ability to select natural colors that enhance the appearance of their outdoor space.

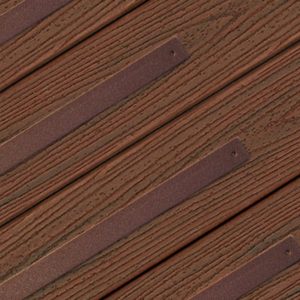

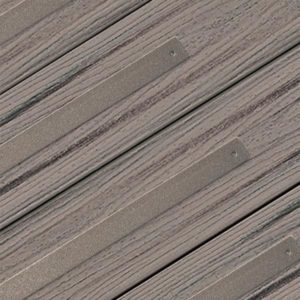

HandiTreads Deck Strips

With that in mind, we’ve developed a new product – the HandiTreads Deck Strips. These 48″ by 1″ aluminum strips have an embedded polyester grit that creates impressive traction.

Available in four designer shades that match popular deck colors, Java Brown, Chestnut Brown, Obsidian Black, and New England Gray, deck strips are the perfect solution for homeowners that value both safety and appearance.

At just $8 per-strip, $30 for a pack of four strips, or $70 for a pack of 10 strips, these powder-coated aluminum traction strips come with color matching screws and can be applied in minutes. The self-cleaning non-slip strips shed water, shred leaves and are resistant to moss and mold. They’re also comfortable on bare feet and paws!

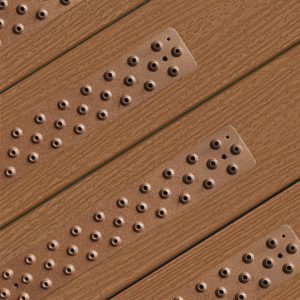

HandiTreads Deck Treads

If your deck is subject to snow and ice collection in the winter, Deck Strips may not provide the best slip and fall protection. HandiTreads Deck Treads on the other hand, were created to provide unbeatable traction on your deck in all seasons and weather conditions. The deck treads measure 48″ long by 1 7/8″ wide and come in the same four earth-toned shades as the Deck Strips mentioned above.

Long, slender and beautiful, Deck Treads provide unbeatable traction in all weather conditions while blending seamlessly into the appearance of the deck. The unique surface of the treads feature patented traction buttons that grip to your shoe or foot in rain, sleet, and up to an inch of snow, ice, or debris. Once installed in the problem areas of the deck you can forget them! They’re safe for both bare feet and dog paws and can be swept, power-washed, and shoveled when the snow falls.

At $15.95 per tread, $60 for a pack of four treads, or $144 for a pack of 10, the Deck Treads are easily installed to your deck using a power drill and the included color-matched screws. With a lifetime warranty, HandiTreads Deck Treads are guaranteed to last a lifetime in your home.

What If My Entire Trex Deck is Slippery?

If most of your Trex Deck is slick, then you’ll need a different solution. The 2012 Trex Installation Guide addresses the issue of a slippery composite decking surface in the following manner.

“If there is an ADA requirement for slip resistance, an appropriate type of paint with grit or grit additive can be applied. For standard Trex decking products, a product like Benjamin Moore®***** Anti-Slip 116 (note this is not clear-based) or an equivalent anti-slip alternative will provide an abrasive coating to materials for ramps that must meet ADA requirements. For Transcend decking, a latex or acrylic-based paint will not adhere but oil-based paint with grit will adhere and provide proper friction properties.”

The 2012 Trex recommendation of painting first-generation Trex decks with enamel paint with grit additive makes sense to us. Assuming the enamel paint with a grit additive will adhere to your particular Trex product, that’s a reasonable for a first-generation Trex deck where nearly the entire surface is slippery. However, if you want a longer-lasting, more resilient traction paint, we recommend the Slip Doctor product line of epoxy grit paint.

Grit paint does wear down over time and if you live in an area with snow, you can’t use a metal snow shovel on the painted surface. Even in the best of outdoor conditions, you can anticipate the need to reapply a coat of grit paint every 5 years or so. Needless to say, the maintenance requirement of grit paint adds to the cost of ownership and is something to consider as choose a proper solution.

Please note that before you apply any grit paint to a slippery Trex deck we strongly recommend that you contact Trex and check the warranty for your specific year of manufacture. We’ve seen recent Trex installation instructions that suggest applying paint to any of their composite decking will shorten or even eliminate the warranty.

Can the Latest Trex Transcend, Enhance, and Select Decking Be Painted With Grit Paint?

In 2014, we noticed a change to the Trex decking installation instructions. Where previously the 2012 installation guide indicated that plastic-capped Transcend decking could be painted with an oil-based grit paint, the 2014 Trex Installation Guide clearly states that paint should not be applied to the Transcend, Enhance and Select Trex decking product lines. This doesn’t necessarily mean that you can’t find a paint that will adhere to the plastic-capped composite decking, but you will almost certainly void your warranty by doing so. Nonetheless, if you’re slipping on your synthetic wood deck, voiding the warranty is the least of your worries.

If your deck is made of Trex composite material that was manufactured after 2012 and you don’t want to void your warranty, then you’ve got two options, each of which has its downside. First, you could use heavy rubber mats, like the ones used in commercial kitchens, in the most highly trafficked areas. Second, you could install our HandiTreads Deck Treads across broad swaths of the deck which could get expensive. Both are imperfect solutions, but they just might save a slip or fall that sends a loved one to the hospital.

If your decking is not in direct sunlight, and you’re willing to scuff-sand the deck and apply a bonding agent first, then the Slip Doctor Dura Grip anti-slip coating, which is bare foot friendly, can adhere to the deck and improve traction

As always, we’re here to help you navigate any slip, trip, or fall hazard with a customized solution designed just for you. Contact us today for a free consultation.

The History of Trex Decking

The residential decking market was valued at $3.1 billion in 2018 and was expected to grow by 6.5% annually through 2021, according to Principia Consulting. Even with the COVID-19 slowdown likely to trim those projections, that’s still a lot of outdoor decks, patios, and stairs!

In the segment of wood-alternative decking material, Trex is the largest single manufacturer with over $680 million in 2018 revenue. Trex holds the original patent for producing a “Wood-Thermoplastic Composite Material” that requires less maintenance and often lasts longer than natural wood.

The first generation Trex boards of the late 1990s began life as recycled plastic, wood dust, and wood chips. These ingredients were then heated and formed into board-type shapes using a heat extrusion process. (Think Playdoh being pushed through a form to create a log of clay.)

The patent application for Trex first-generation composite decking highlights the following unique characteristics:

“(Trex composite decking) may be used in many of the same applications as an all-wood product but offer the advantages of providing high resistance to rot, insects, and moisture. These products can have the same workability as wood and are splinter-free.”

Indeed, Trex marketed the original composite decking, which was several times more expensive than treated lumber, based on the longevity of the product and low maintenance required. Over the years Trex has acquired tens of thousands of satisfied customers, but they also have faced a class action lawsuit which claimed that the non-shelled, wood-plastic composite decking was, according to the lawsuit:

“defective and susceptible to mold, mildew, fungal, or other dark or gray growth or spotting, or color variation or color fading…”

The recently settled legal matter focused on the propensity of the first generation, uncapped Trex boards to grow mold, mildew, and discolor over time. It’s possible that the propensity of the first generation Trex decking to allow the growth of mold and mildew might have been a factor in some Trex decking to be slippery, depending on the environmental conditions.